Our offer for the assembly of mechanical parts

OUR OFFER FOR THE ASSEMBLY OF MECHANICAL PARTS

With our own assembly unit in Mérignac FRANCE, we offer our customers the possibility of having a finished product delivered, tested and packaged for immediate use. Our aim is to support industrials like you, by giving you cost-effective assembly solutions adapted to your project.

Our subcontracting and assembly company is surrounded by qualified partners who manufacture machined parts, plastic parts, aluminium foundries and surface treatment companies to assemble your finished part projects in a very competitive lead time.

AS Industries design its own assembly methods, tools, jigs and workstations, right through to bespoke packaging to efficiently meet your industrial parts requirements.

OUR ASSEMBLY TEAM

Methods and Assembly Manager

Located in Mérignac, our assembly department is in direct link with AS Industries teams and benefits from the purchasing, quality control and logistic skills of our employees. The assembly service is supervised by the Quality department, which ensures compliance with procedures and additional control of the parts.

The method manager designs and defines the means to carry out the assembly of projects with the help of a team of 3 dedicated assembly operators.

THE ASSEMBLY UNIT EXPANDS TO MEET YOUR DEMANDS

AS Industries is expanding its assembly unit. After a year rich in requests for assembly, we decided to expand our premises by creating two new assembly lines. Assembly better satisfy our customers and prospects by innovating and offering new services. That is why we offer you the assembly of your sets, sub-sets and mechanical components.

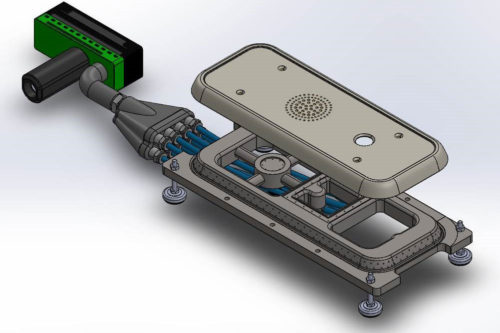

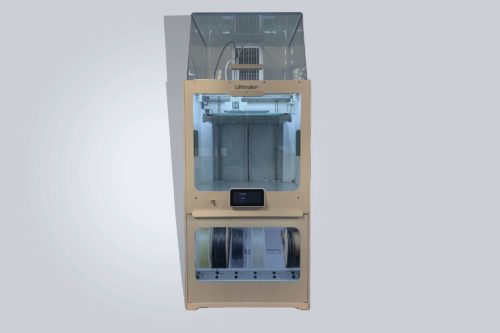

Our assembly activity is already ISO 9001 certified, and benefits from the best practices of the aeronautics sector such as the management of special processes (riveting, bonding…). We adopt an approach of continuous improvement for each project by imagining specific means, poka yoke (tooling) to measure obtained via our 3D printer. We are constantly working on ergonomics at the workstation by following the Lean method.

With our assembly unit we give you agility on your project, our teams will be reactive to offer a service from assembly of mechanical parts to measure of quality.

EXAMPLE OF ASSEMBLY

THE QUALITY OF AS INDUSTRIES, SPECIALIST FOR NOW 20 YEARS

AS Industries is a specialist in the subcontracting of mechanical parts in China. Certified ISO 9001 and EN 9100, we ensure the safety and quality of your parts in precision machining processes, foundry, sheet metal, plastics and MIM.

With 20 years of experience, AS Industries offers its know-how and provides small, medium and large companies with solutions to solve their manufacturing problems and optimize the manufacturing costs of their mechanical parts while ensuring their quality.

We offer, as previously mentioned, related services such as assembly or storage of your parts.

DEADLINES

Once we receipted your assembly request, we estimate the assembly time required for your mechanical parts. You will get an answer within a week. We take into account all the steps from the initial plan review to the quality control of the assembly of the finished product, all in conjunction with our suppliers.

OUR GUARANTEES

100% DIMENSIONAL CONTROL

100% DIMENSIONAL CONTROL

We are equipped to control all types of dimensions and guarantee a 100% control of the dimensions on the plan, especially on the first parts.

CAPABILITY STUDY

CAPABILITY STUDY

From a drawing, we evaluate the measurements of your part, in order to validate its geometric conformity.

COMPARISON OF DEVIATIONS FROM THE 3D MODEL

COMPARISON OF DEVIATIONS FROM THE 3D MODEL

We can easily compare the dimensions measured by our inspectors with the 3D model of the part and produce a report that accurately represents each deviation.

EXTERNAL TESTS (TENSILE STRENGTH, CORROSION / SALT SPRAY TEST, ….)

EXTERNAL TESTS (TENSILE STRENGTH, CORROSION / SALT SPRAY TEST, ….)

We can carry out all types of corrosion or fatigue tests thanks to qualified external laboratories.

1ST ARTICLE FILE

1ST ARTICLE FILE

The first article control, also called FAI or DVI, allows to check that the manufacturing process is able to produce parts in series according to the specifications, in accordance with the customer’s request.

MATERIAL TEST REPORT FROM OUR SPECTROMETER

MATERIAL TEST REPORT FROM OUR SPECTROMETER

Our mass spectrometer is able to analyse the chemical composition of chemical alloys to avoid any risk of material counterfeiting.

REACH / ROHS CERTIFICATES

REACH / ROHS CERTIFICATES

We certify that the delivered parts comply with the European RoHS directive.