Quality control

AS INDUSTRIES CHECKS THE CONFORMITY OF YOUR PARTS IN ITS QUALITY CONTROL LABORATORY IN FRANCE.

AS Industries is ISO 9001 and EN 9100 certified in order to guarantee a robust organization and the consideration of specific industry issues such as:

- The respect of the lead-times

- The control of the conformity of the delivered parts

- Risk analysis

- The fight against counterfeits parts

The conformity of each batch is checked by a team of qualified dedicated inspectors in an adapted environment, using a full step control.

All the controls carried out are archived and available at any time for our customers. We check the characteristics of the product as well as the conformity of the associated documentation (material certificates, processing certificates, mechanical tests…).

FOR 20 YEARS, AS INDUSTRIES HAS BEEN DEVELOPING ITS KNOW-HOW AND EXPERTISE TO MEET YOUR REQUIREMENTS.

We are able to provide any type of inspection report:

- 100% dimensional

- Capability study

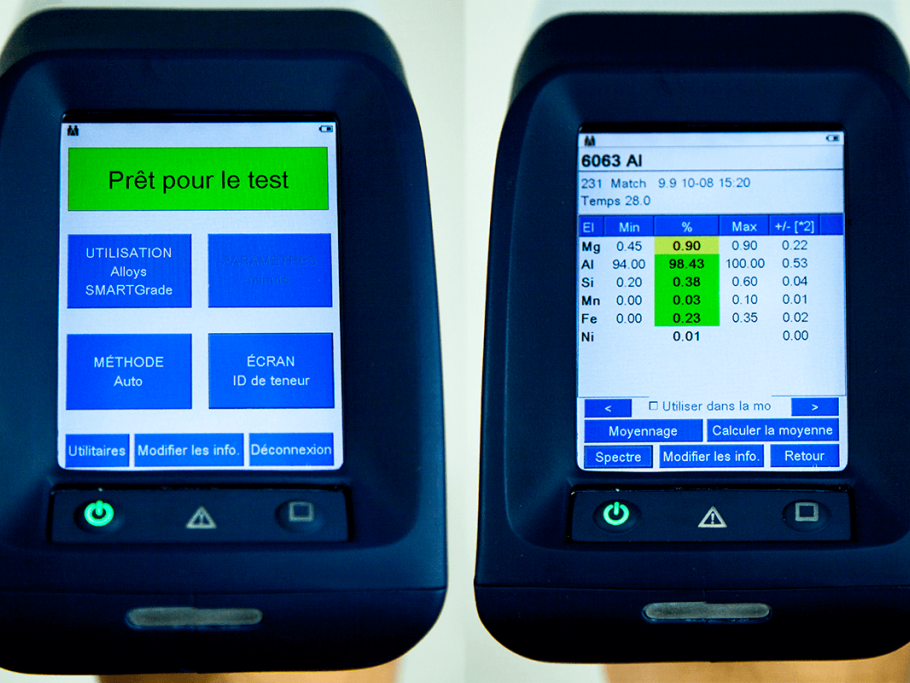

- Material test report from our spectrometer

- 1st article report

- Comparison of deviations from the 3D model

- External tests (tensile strength, corrosion / salt spray test, ….)

- REACH / RoHS certificates

- We ensure a complete traceability of the control records:

- Qualification of the controller

- Tools used and calibration certificates

- Batch number and quantity taken

- Values measured

- Good for shipment

HIGH PERFORMANCE EQUIPMENT

We regularly invest in our laboratory equipment to offer control methods adapted to our customers’ needs:

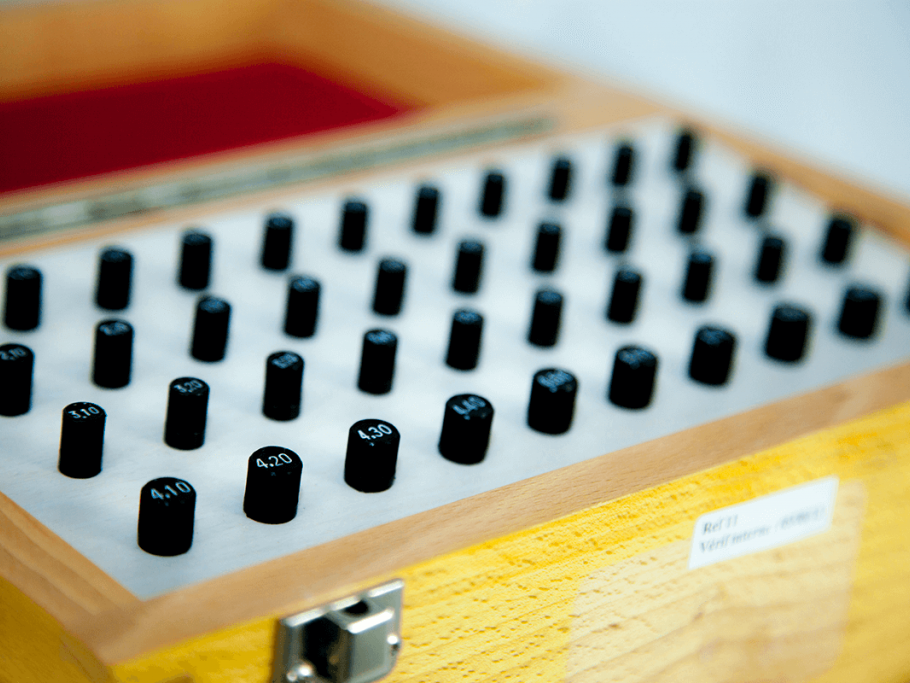

- Dimensional control:

- 3D control machine KEYENCE

- Measuring columns

- Profile projector

- Standard metrological tools (micrometers, reameters…)

- Material control on metallic parts with a spectrometer:

- Aluminum grades

- Stainless steels

- Copper alloys, …

- Roughness device, Hardness device, thickness control of surface treatment.

- Realization of specific templates

- Appearance control and elaboration of complete defect libraries.

In the context of first parts, AS Industries is able to accompany its customers and propose design optimizations:

- To improve repeatability in production

- To reduce the risks of non-conformity

- To reduce part weight

- To facilitate part inspection

These first parts will then be 100% checked by our teams and accompanied by a complete sample file to validate this first delivery.

Our control procedures are regularly audited and our teams are constantly monitoring new control methods to improve efficiency and measurement accuracy.

The involvement of our teams in this complete quality process, from the selection and qualification of our suppliers, through the control of each batch to the final shipping authorization, is regularly qualified as a strong point by our customers.

THE QUALITY CONTROL TEAM

In order to satisfy your requirements, AS Industries’ quality control team is in charge of controlling your parts as soon as they are received in Bordeaux.

Our team is here to answer all your questions and requests: contact@asindus.com or by phone at +33 (0)5 40 01 76 00