Our manufacturing process development and design to cost offers

Work with a dedicated technical referent throughout your project

AS Industries’ Design to Cost offer, allows you to optimize your mechanical parts from the design phase to the production stage.

AS Industries is here to guide you: our technical referents help you to adapt your part design and integration that will suit your specific needs.

We help you to validate the proper definition in accordance with your margin’s improvement targets.

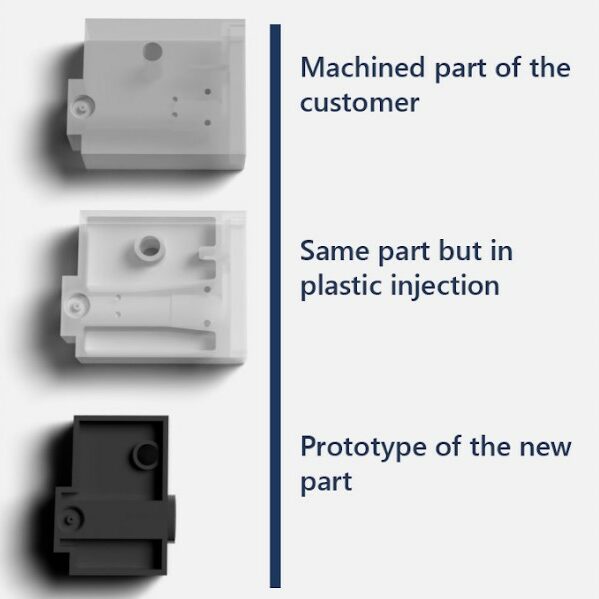

Design to Cost example: the following part has been reworked many times: from bottom to top.

AS INDUSTRIES: MECHANICAL PART SUPPLIER SINCE 2003

For 20 years, AS Industries is your specialist in mechanical part subcontracting from China. ISO 9001 and EN 9100 certified, we guarantee quality and transparency of your goods produced by precision machining, die casting, sheet bending, plastic molding and MIM.

With our deep-rooted experience, AS Industries is turning its knowledge into action by offering tailored solutions to deal with manufacturing issues and costs, while assuring quality standard, for both SMEs and large companies.

We also provide in house assembly and warehousing.

OUR REFERENTS

Technical referent and industrial designer since 1999

Die casting specialist as well as other processes

Technical referent and industrial designer since 2015

Plastic molding specialist as well as other processes

WHY AS INDUSTRIES? 20 YEARS OF EXPERIENCE

20 years of experience

20 years of experience

Given the complexity in terms of design, material and costs target, part manufacturing can be challenging and time-consuming. That is why AS Industries and its team of Technical Referents is here to find the most suitable solution to your requirements.

With 20 years of experience, our technical expertise is a real asset for your upcoming projects.

Costs and weight reduction

Costs and weight reduction

By switching from a CNC Machining process to a Die-Casting process, you can reduce costs up to 2,5 times.

Lead times

Lead times

As soon as we get your request, we will estimate the amount of time required to complete your project. From the early stage of need analysis to the final drawings’ revue, in partnership with our suppliers.

Reliable suppliers

Reliable suppliers

For 20 years AS Industries has been working with ISO9001 certified suppliers, ensuring reliability and reactiveness.

Our engagements

Our engagements

AS Industries will provide you every requested control reports:

- 100% dimensional control

- Capability analysis

- Material identification report from our X-ray Fluorescence analyzer

- First article inspection (FAI) report

- Deviations identification from a 3D model

- Subcontracted tests (stress test, corrosion test / salt spray,….)

- REACH / RoHS Certificates

A PROJECT LIFE CYCLE AT AS INDUSTRIES

A manufacturing project is when our client expresses the need for 2D drawings and 3D models of a specific mechanical part.

Project-based working allows a unique communication between our design office, the customer and the supplier.

At AS Industries, our technical referent will remain your only contact. He will be in charge of the following milestones: